Waukesha, WI

Tuesday, February 16, 2010

Friction Stir Welding (FSW) & Processing in Navel Combatant Construction

John Hinrichs and Bruce Halverson

Monolith Engines

Tom Dougherty

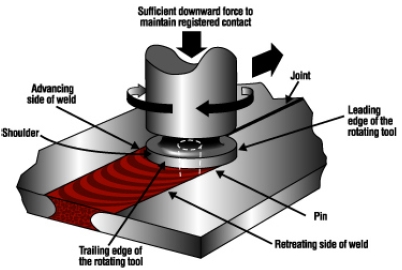

Friction Stir Welding (FSW) & Processing in Naval Combatant Construction

Presenters Names: Bruce Halverson, Marinette Marine Corporation & John Hinrichs, Friction Stir Link, Inc.

ABSTRACT

The United States Navy’s Littoral Combat Ships (LCS’s) represents a new direction in military capabilities and ship design. The lessons learned in friction stir welding of the deckhouse and superstructure extruded aluminum 5XXX series aluminum panels of the USS Freedom LCS #1 and USS Fort Worth LCS#3 will be discussed. Cost reduction ideas such as friction stir weld classifications, proposed inspection of friction stir welds classes to produce lower cost panels and friction stir processing to produce lower cost stiffeners will be presented. The actual experiences with friction stir welding of LCS#1 and LCS#3 deckhouse and superstructure panels have resulted in ideas and concepts to improve the affordability of future LCS and other aluminum ship structures. Discussions of NDT methods as applied to Friction Stir Welding will also be covered.

BIOGRAPHY

John F. Hinrichs PE, CMfgE, FAWS

John is a founder of the Friction Stir Link, Inc. (FSL) started in April of 2001 and is the principle consultant and owner of The Welding Link beginning in 1995. Prior to forming the Friction Stir Link, Inc., and The Welding Link, Hinrichs was affiliated with A.O. Smith Corporation for more than 40 years. Hinrichs holds fifteen (15) U.S. and three (3) foreign patents related to welding processes. In 1989, he was the first American to be presented the Golden Robot Award at the International Symposium of Industrial Robots held in Tokyo. He received the American Welding Society (AWS) Safety and Health Award in 1998 and was the first recipient of the AWS Robotic and Automatic Arc Welding Award in 2004. His professional activities are extensive and include serving as Director At Large of the American Welding Society, and Chair of both AWS Safety and Health and Technical Papers Committees. His current affiliations include ASME, AWS, ASM International, RIA-SME, and IIW.

Hinrichs received his degree in Mechanical Engineering from Marquette University in 1956 and his master’s in Metallurgical Engineering from the University of Wisconsin in 1964. He is a registered Professional Engineer in Wisconsin, a Certified Manufacturing Engineer, and a Fellow of the American Welding Society.

Bruce Halverson

Bruce is the Quality Assurance Manager of Marinette Marine Corporation. He is responsible for all hull structure including welding, machinery, electrical and outfitting. He is also the Corporate ASNT Level III Examiner in four Nondestructive testing methods. Bruce has been an AWS Certified Welding Inspector since May 1978. He attained Level III status as an American Society of Nondestructive Testing Examiner in 1979 for Radiographic, Ultrasonic, Penetrant and Magnetic Particle methods. He has 34 years of shipbuilding and general fabrication experience including AWS, ASME, and DoD standards. He was the first to pioneer Ultrasonic testing with a real time record on VHS tape. He has served as the Welding/NDT Engineer for 41 major vessels totaling over 1.75 million tons of steel and aluminum. He has also run his own company in NDT and Weld Consulting. He is known for pushing the technology in both welding and nondestructive testing to lower costs while providing quality improvements during the process. He is currently pioneering a pulsed Radiographic Computed Digital Imaging System to lower worker exposure during the process of volumetric inspection on thin structures where Ultrasonic acceptance standards currently do not exist.

Bruce received his A.S. Degree from Madison Area Technical College – Industrial Welding Technology 1974.

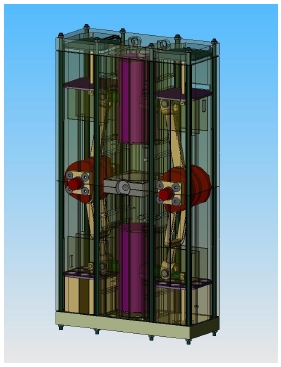

Monolith Engines Inc.

Presenters Names: Tom Dougherty

ABSTRACT

MEI is an energy conservation and conversion consulting company presently assisting 6 major companies in their product development concentrating in the battery, capacitor and energy generation field. The presentation will be on the design and development of new patented method of energy transfer in engines, pumps and compressors. The Monolith Engine is unique in the way it transfers power from the newly designed piston heads through the piston rods to the dual crankshafts. With this type of transfer, the pistons travel straight up and down, significantly reducing friction. Thinking “outside the cylinder” was the way to accomplish these goals. This design should be able to reduce larger engines dramatically in both is size and weight.

The presentation will cover the 18 year history of the engines development from the Gen I design to the present Gen II design. Tom will also talk about the present oil-less gas two-cycle to the proposed four cycle while also discussing the remaining challenges, or Tom’s puts it, opportunities of this new construction. The presentation includes an actual computer building of the entire engine in Solid Works and the first two prototypes build of the Gen I design.

BIOGRAPHY

Tom Dougherty

Tom is the President of Monolith Engines Inc. in Waukesha Wisconsin. Prior to MEI Tom was Director of Advance Battery and Hybrid Systems at Johnson Controls Inc. Many of you may remember about 5 years ago when Tom hosted the tour and presented at JCI.

Tom presently has 45 patents in 6 different fields of technology including: software, electronics, battery design, chargers and test equipment, system and equipment development, alternators and engine design.

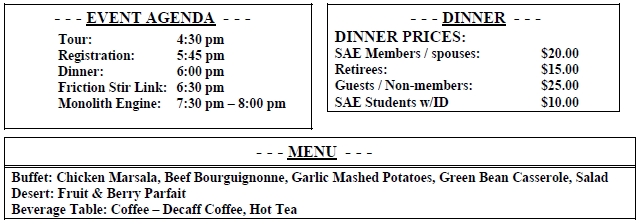

Only pre-payments made with a charge card can be completed online via www.milwaukeesae.com

Retirees, students and members without web access may register by phone on the SAE Registration Coordinator – Jim Ryan (262) 636-1634.

Registration deadline: Sunday, February 14, 12:00 p.m.

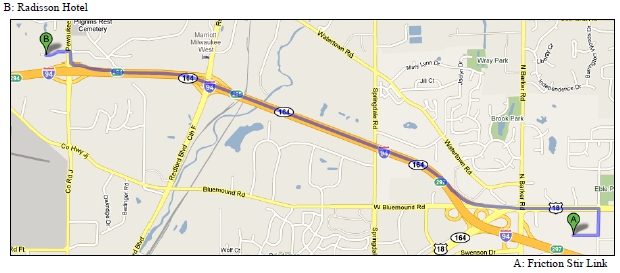

Directions to: Friction Stir Link – Tour

19775 Sommers Dr

Brookfield, WI 53045

Take exit 297 off I94 toward US-18/WI-164. Take a slight right from the exit ramp onto N Barker Road. Take the first right onto W Bluemound Road/US-18E and go about 1/4 mile to intersection with Janacek Road and turn right. Go about 2 blocks to the intersection with Sommers Drive and turn Right. Go to the far end of Sommers Drive (2 blocks) to the long building with the letters BFG on it. Turn left at the end of Sommers Drive. Enter the Friction Stir Link building at the southeast corner of the building.

Directions to: Radisson – Presentation

N14 W2414 Tower Place

Waukesha, WI 53188

Leave Friction Stir Link by heading east on Sommers Drive towards Janacek Road. Take a left at Janacek Road. Take the first left onto W Bluemound Road/US-18W. Take the ramp onto I-94W. Take exit 294 for WI-164 North. Turn right at Pewaukee Road/164 north. Take the first left onto Stonridge Drive. Continue onto Tower Place. Once inside the Radisson hotel, the SAE meeting will be held in the Lake Nagawicks and Lake Okauchee rooms.