Challenge of Emissions Certification for Small Engine Manufactuers

Kohler, WI

Wednesday April 21st, 2010

TOUR OF THE TEST LAB & TECHNICAL PRESENTATION

Kohler Engines has been manufacturing small engines since 1920. In this long history, the industry has faced many technological challenges, but none may be as far reaching as the changes required on the road to green emissions. The base technology has largely been developed by the automotive industry (water cooled engines), but some of the technology is not directly applicable to the small engine industry for air cooled engines.

The regulatory emissions requirements for small engines read like the Federal Tax Code (or more recently, the Health Care Reform Act). The rules are different for the Environmental Protection Agency (EPA), the California Air Resource Board (CARB), the European Community and for fast developing markets in China and India. The regulations are also different by displacement, by horsepower and by type of applications. An overview of regulations will be discussed in the presentation.

Small engines, like automotive, are regulated to limit the exhaust emissions from the combination of hydrocarbons and oxides of nitrogen (HC +NOx). In most cases, emissions improvements are rooted in the details of the base engine design. Some of these impacted components will be discussed in this presentation.

Biography: Steve Riese

As Senior Staff Engineer at Kohler Engines, Steve leads the Emissions engineering team which is responsible for the development and execution of the strategic plans and tactical plans for emissions compliance. Steve has been in the engine business for over 30 years. Prior to Kohler, Steve worked for Mercury Marine in a range of roles including R&D Engineer, Base Powerhead Specialist, Project Engineer, Current Product Manager, and Program Manager. Notable were leading roles on the 3.0L V6 two-stroke outboard, the 1.5L L3 two-stroke outboard engine, and the Asia resourcing of the 995cc I4 and 747 cc I3 four-stroke outboard engines. In the last four years at Kohler Engines, Steve has been challenged to reduce the exhaust and evaporative emissions of air-cooled, four-stroke engines ranging from 200cc lawnmower engines to 999cc V-twin industrial engines.

Steve holds a BS in Mechanical Engineering from the University of Wisconsin and an MBA from the UW-Oshkosh.

Dennis Nitz

As a Mechanical Project Engineer in the emissions group at Kohler Engines, Dennis is responsible for helping to determine emission reduction technologies on several engine platforms, heads the emissions audit program and is responsible for analyzing and creating the strategic emissions plan for emissions compliance. Dennis came to Kohler 2 years ago from the Engine Research Center at UW Madison where his research focused on extending the HCCI (Homogeneous Charge Compression Ignition) operating range by exploring methods to control the rate and inception of spontaneous combustion. He also gained experience in small internal combustion engines as a Co-op in the Fuel Systems and Calibration groups at Mercury Marine and Polaris Industries. He was a 4 year member on the Formula SAE team at UW Madison where he was active on the Suspension and Power train Teams. Over the last 2 years at Kohler, Dennis has rapidly learned the scope of emissions on small internal combustion engines including regulatory requirements and has lead the emissions effort to bring two new engine projects to emissions compliance. He has also completed a 6 month rotation as a Development Engineer in the New Product Engineering group at Kohler.

Dennis holds a BS in Mechanical Engineering from the UW Madison and an MS degree in Mechanical Engineering from the Engine Research Center at UW Madison.

Registration: Only pre-payments made with a charge card can be completed online via https://fkc.sfg.mybluehost.me.

Retirees, students and members without web access may register by phone on the SAE Regisistration Coordinator – Jim Ryan (262) 636-1634. Max attendance for this event is TBD.

Registration deadline: Monday, April 19, 12:00pm.

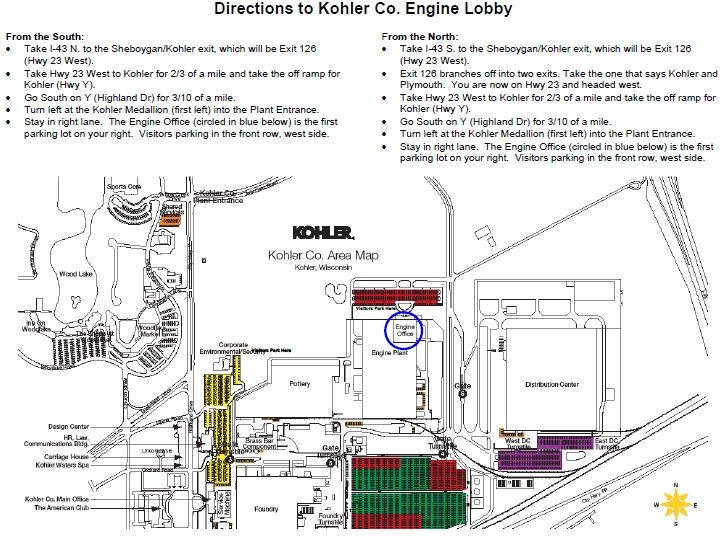

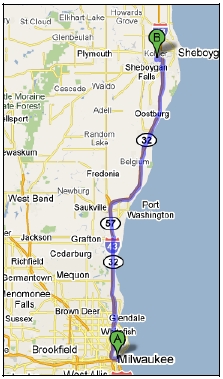

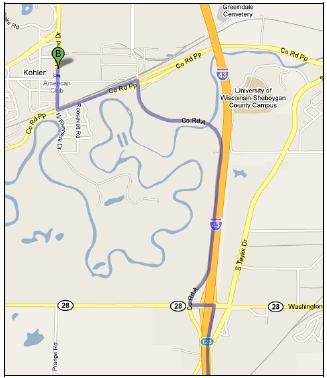

Directions to Kohler Engines

Kohler Co

444 Highland Dr, Kohler, WI 53044